5. Connecting supported non-Victron products

5.1. Connecting a PV Inverter

Measuring the output of a PV Inverter will provide the user with an overview of both actual power balance and the energy distribution. Note that these measurements are only used to display information. They are not needed nor used by the installation for its performance. Besides monitoring, the GX device can also curtail some types and brands of PV Inverters, ie. reduce their output power. This is used, and required, for the ESS Zero or limited feed-in feature.

Direct connections

Type | Zero feed-in | Details |

|---|---|---|

Fronius | Yes | LAN Connection, see GX - GX - Fronius manual |

SMA | No | LAN Connection, see GX - GX - SMA manual |

SolarEdge | No | LAN Connection, see GX - SolarEdge manual |

ABB | Yes | LAN Connection, see GX - ABB manual |

Using a meter

For PV Inverters that cannot be interfaced digitally, a meter can be used:

Type | Zero feed-in | Details |

|---|---|---|

No | Connected to inverter/charger analog input. Lowest cost - least accurate. Energy Meter | |

No | Wired to the Cerbo GX, or connected wirelessly using our Zigbee to USB/RS485 converters. See the Energy Meters start page | |

Wireless AC sensors | No | See the Wireless AC Sensor manual - Discontinued product |

5.2. Connecting a USB GPS

Use a GPS to remotely, on the VRM Portal, track vehicles or boats. Also its possible to configure a Geofence, which will automatically send an alarm when the system leaves a designated area. And gps-tracks.kml files can be downloaded to open them e.g. in Navlink and Google Earth.

Victron does not sell USB-GPS modules, but the Cerbo GX support third-party GPS modules which use the NMEA0183 command-set - almost all do. It can communicate at both 4800 and 38400 baud rates. Plug the unit into either of the USB sockets. Connection may take a few minutes, but the Cerbo GX will automatically recognize the GPS. The unit's location will automatically be sent to the VRM online portal and its position is shown on the map.

The Cerbo GX has been tested for compatibility with:

Globalsat BU353-W SiRF STAR III 4800 baud

Globalsat ND100 SiRF STAR III 38400 baud

Globalsat BU353S4 SiRF STAR IV 4800 baud

Globalsat MR350 + BR305US SiRF STAR III 4800 baud

5.3. Connecting a NMEA 2000 GPS

Instead of a USB GPS, a NMEA 2000 GPS can be used for remote vehicle or boat tracking in the VRM portal.

The third party NMEA 2000 GPS sender must meet the following requirements:

The NMEA 2000 device class must be 60, Navigation.

The NMEA 2000 device function must be 145, Ownship Position (GNSS).

Position (latitude, longtitude) must be transmitted in PGN 129025.

Height, which is optional, must be transmitted in PGN 129029.

Course and speed (both optional), must be transmitted in PGN 129026.

Most NMEA 2000 GPS-es are expected to work. Compatibility has been tested with:

Garmin GPS 19X NMEA 2000

To connect a NMEA 2000 network to the VE.Can port on the GX device, which both have a different style connector, there are two solutions:

The VE.Can to NMEA 2000 cable. Which by either inserting or leaving out the fuse allows to either power the NMEA 2000 network with Victron equipment, or not. Take note of below warning.

The 3802 VE.Can Adapter by OSUKL. Its advantage is that it lends itself well to connecting a single NMEA 2000 device such as a tank sender into a VE.Can network. It's also able to power a lower voltage NMEA 2000 network directly from a 48V Victron system.

Warning and solution for 24V and 48V systems

Whilst all Victron components accept up to 70V input on their CAN-bus connections, some NMEA 2000 equipment does not. They require a 12V powered NMEA 2000 connection, and sometimes work up to 30 or 36V. Make sure to check the datasheet of all used NMEA 2000 equipment. In case the system contains NMEA 2000 that requires a network voltage below the battery voltage, then either see above 3802 VE.Can Adapter by OSUKL, or alternatively install the VE.Can to NMEA 2000 cable without it’s fuse, and provide suitable power to the NMEA 2000 network using for example a NMEA 2000 power adapter cable – which is not supplied by Victron. The VE.Can port on the GX device does not need external power to operate.

5.4. Connecting A Fischer Panda Generator

For detailed information, see here.

5.5. Connecting Tank Level Sensors to the GX Tank Inputs

The tank level inputs are resistive and should be connected to a resistive tank sender. Victron does not supply tank senders. The built-in tank sensor connections do not support mA or 0-5V type sensors, this type will require additional accessories or replacement with a resistive type sensor.

Sensors are enabled (and disabled) in the I/O menu (Settings → I/O → Analog input) of the GX device settings. Once enabled, the tank will appear in the Device List with options to customise the setup to suit your specific installation.

Set the tank volume unit (Cubic meter, litre, imperial or U.S gallon), and capacity. It is also possible to configure custom shapes for non-linear tanks, with up to 10 variations e.g 50% of sensor is equal to 25% of volume & 75% of sensor is equal to 90% of volume.

The tank level ports can each be configured to work with either European (0 - 180 Ohm); or US tank senders (240 - 30 Ohm) standards; or to configure a custom Ohm resistance range between 0 Ohm and 300 Ohm (requires firmware v2.80 or higher).

You can set tank fluid type to Fuel, Fresh water, Waste water, Live well, Oil, Black water (sewage), Gasoline, Diesel LPG, LNG, Hydraulic oil and Raw water and also set a custom name.

A separate low or high level alarm can be set and activated for each tank sensor.

Tank level data is sent to the VRM Portal, shown on the boat and motorhome overview display (if connected and enabled), and can be used as a trigger for the relay when it is set to 'Tank pump'. Tank levels can also be monitored at various other locations within the GX environment:

Device List of the GX device

Sensor overview menu of the GX device

Graphical overview of the GX device

VRM Dashboard

VRM advanced menu widgets

VRM App widgets

|

To physically attach the tank probes requires a ferrule or exposed copper end of at least 10 mm+ to be inserted into the removable terminal block connector. Once correctly attached, you must use the orange tab if you wish to remove the secured wire.

5.6. Increasing the number of tank inputs by using multiple GX devices

5.6.1. Introduction

The number of tank inputs on a GX device, such as the Cerbo GX and Venus GX, can be expanded by connecting multiple GX devices together in a VE.Can network. To do this, one GX device must be designated to be the "main" and the others(s) to be the "secondary" one(s). How this is done in practice is explained below.

There is no practical limit on how many GX devices can be used - except for the number of source addresses available in a VE.Can network, which is 252 addresses. For example, a Cerbo GX with 4 tank inputs uses up to 5 addresses: one for itself and one for each tank input.

5.6.2. Requirements

Only enable the MQTT settings (part of MFD App integration) on one of the GX devices, not multiple.

Only connect the main GX device to the Ethernet network - do not connect the others. The MFD App on Marine MFDs is not designed to work with multiple GX devices on one Ethernet network.

In case you are using the ModbusTCP protocol: Enable ModbusTCP on only one of the GX devices.

Only connect the main GX device to VRM; it will also transmit tank levels received from the secondary units.

We recommend connecting all VE.Bus and VE.Direct products to the main GX device. Connecting through a secondary device works, but has limitations. For example, remote configuration doesn't work, DVCC control will not work, and remote firmware updates don't work either. Extending the VE.Direct ports via USB provides full functionality, which is therefore the recommended method. You can find more information on this in chapter Powering the Cerbo GX.

5.6.3. Configuration step-by-step

First, on all GX devices, configure all tank inputs in Settings → I/O → Analog input, only enable the inputs in use, disable the others.

In Device List → Tank input → Device → Name, give each tank input its own unique proper name, ie Fresh water 1, Gray water SB, Diesel Port, and so forth.

This is the only way to make sure they are distinguishable once all connected together.

Connect each GX device together on its VE.Can port and make sure to terminate on both ends.

There is no need to power the VE.Can network externally: while the GX devices don't power the VE.Can network, they do power their own internal CAN circuitry.

Now, on each GX device go to Settings → Services → VE.Can and there:

Verify that the chosen profile is VE.Can & Lynx Ion BMS (250 kbit/s) or VE.Can & CAN-bus BMS (250 kbit/s)

Enable the NMEA2000-out feature on all GX devices

Assign each GX device its own unique number

Use the Check Unique id numbers test feature when to make sure all went well

Lastly, on the main GX device, check if all sensors show up in the Device List and work well.

5.7. Connecting third-party NMEA 2000 tank senders

A third-party NMEA 2000 tank sender must meet the following requirements to be visible on the GX device:

Transmit the NMEA 2000 Fluid Level PGN, 127505

The NMEA 2000 device class needs to either General (80) in combination with function code Transducer (190), or Sensor (170). Or, the NMEA 2000 device class needs to be Sensors (75), in combination with function Fluid Level (150).

A single function reporting multiple Fluid Levels is currently not supported.

For some tank senders it is also possible to configure the capacity and the fluid type on the GX Device menus - for example the Maretron TLA100. This facility may be available with other senders made by other manufacturers - it's well-worth trying.

Tested compatible NMEA 2000 tank senders:

Maretron TLA100

Maretron TLM100

Navico Fluid Level Sensor Fuel-0 PK, partno. 000-11518-001. Note that you need a Navico display to configure the Capacity, Fluid type, and other parameters of the sensor. See voltage warning below.

Oceanic Systems (UK) Ltd (OSUKL) - 3271 Volumetric Tank Sender. In case it doesn’t work, it needs a firmware update. Contact OSUKL for that. See voltage warning below.

Oceanic Systems UK Ltd (OSUKL) - 3281 Water Level Sender. See voltage warning below

Most likely others work as well. If you know of one working well, get in touch with us on Community -> Modifications.

To connect an NMEA 2000 network to the VE.Can port on the GX device, which both have different type connectors, there are two solutions:

The VE.Can to NMEA2000 cable. Which by either inserting or leaving out the fuse allows to either power the NMEA 2000 network with Victron equipment, or not. Take note of below warning.

The 3802 VE.Can Adapter by OSUKL. Its advantage is that it lends itself well to connecting a single NMEA 2000 device such as a tank sender into a VE.Can network. It's also able to power a lower voltage NMEA 2000 network directly from a 48V Victron system.

Warning and solution for 24V and 48V systems

Whilst all Victron components accept up to 70V input on their CAN-bus connections, some NMEA 2000 equipment does not. They require a 12V powered NMEA 2000 connection, and sometimes work up to 30 or 36V. Make sure to check the datasheet of all used NMEA 2000 equipment. In case the system contains NMEA 2000 that requires a network voltage below the battery voltage, then either see above 3802 VE.Can Adapter by OSUKL. Or alternatively install the VE.Can to NMEA2000 cable without it’s fuse, and provide suitable power to the NMEA 2000 network using for example a NMEA 2000 power adapter cable – which is not supplied by Victron. The VE.Can port on the GX device does not need external power to operate.

5.8. Mopeka Ultrasonic Bluetooth Sensors

Mopeka sensor support has been added to Venus OS. These ultrasonic sensors use BLE (Bluetooth Low Energy). This wireless technology allows devices to be networked within a range of about 10 meters, while consuming significantly less power than ordinary Bluetooth technology.

The Mopeka sensors feature ultrasonic sensing for pressurised and non-pressurised tanks and various tank commodities. Depending on the model, the sensors are attached to the bottom or top of the tank. The liquid level, temperature and sensor battery voltage are streamed wirelessly to the GX device.

Compatible Mopeka sensors

Mopeka sensor | Remarks |

|---|---|

Mopeka Pro Check H2O | |

Mopeka Pro Check LPG | |

Mopeka Pro Check Universal | Requires Venus OS v3.14 minimum |

Mopeka TD40 / TD 200 | |

Mopeka Pro Plus | |

Mopeka Pro 200 |

Note

Only the sensors listed above are supported. Other Mopeka sensors, even if they have Bluetooth, are not supported.

To connect the Mopeka sensors to the GX device via Bluetooth, the GX device needs Bluetooth functionality. Some GX products already have built-in Bluetooth, all others can easily be retrofitted using a standard USB Bluetooth adapter (see the Victron GX product range overview for GX products that have built-in Bluetooth).

However, an additional USB Bluetooth adapter, also for GX devices with built-in Bluetooth, allows for limited relocation of the Bluetooth radio (via a USB cable extension) close to other supported Bluetooth devices that might not otherwise be reachable.

Note for Cerbo GX units built up to and including serial number HQ2207; The built-in Bluetooth connection is disabled when the internal CPU temperature exceeds 53 degrees C (influenced by load and/or ambient temperature). For reliable operation it is necessary to use a USB Bluetooth adapter. Devices manufactured later (HQ2208 and later) do not require an additional USB Bluetooth adapter. Note that this limitation does not apply to the Cerbo-S GX.

USB Bluetooth adapters that have been tested and known to work:

USB Bluetooth adapter | ||||

|---|---|---|---|---|

Insignia (NS-PCY5BMA2) | Logilink BT0037 | TP-Link UB400(UN) | Kinivo BTD-400 | Ideapro USB bluetooth adapter 4.0 |

Ewent EW1085R4 | Laird BT820 | Laird BT851 | - | - |

A list of additional adapters that are also being tested, as well as adapters that have been tested and are known not to work, is available here: Victron Community.

5.8.1. Installation

The installation of the Mopeka sensor is very simple. First, however, the sensor must be installed according to Mopeka's installation instructions and configured via the Mopeka Tank app (available in Google Play and Apple App Store). Then the installation and configuration is done in the GX device as described below.

Make sure Bluetooth is enabled in the Bluetooth sensors menu (enabled by default).

Go to Settings → I/O → Bluetooth sensors menu.

Move the Enable slider to the right to enable Bluetooth sensors.

To find your Mopeka sensor, scroll down until you see them.

To activate the sensor, move the slider to the right. It should now appear on the Device List.

Repeat steps 1..5 for more than one sensor.

5.8.2. Configuration

Go to the Device List menu.

Scroll up or down and select the appropriate sensor.

Press the right arrow key or space bar on that sensor to open up the sensor Setup menu.

Scroll down to Setup and right arrow key or space bar again to open up the sensors Setup menu.

In the Setup menu you can change the tank capacity, select the liquid type and volume unit, set up calibration values for empty and full tank levels and read the actual sensor value.

After setup, go back to the Sensor overview menu.

Scroll down, select Device and press the right arrow key or space bar again to open up the device settings menu.

In the Device menu you can assign a custom name to the sensor and read out some additional device information.

Repeat steps 1..8 if you want to set up additional sensors.

5.8.3. Tank level monitoring

Tank levels can be monitored at various locations within the GX environment:

Device List of the GX device

Sensor overview menu of the GX device

Graphical overview of the GX device

VRM Dashboard

VRM advanced menu widgets

VRM App widgets

5.9. Wireless Bluetooth Ruuvi temperature sensors

The Ruuvi sensor features temperature, humidity and atmospheric pressure streamed wirelessly to the GX device via Bluetooth.

To connect the Ruuvi sensors to the GX device via Bluetooth, the GX device needs Bluetooth functionality. Some GX products already have built-in Bluetooth, all others can easily be retrofitted using a standard USB Bluetooth adapter (see the Victron GX product range overview for GX products that have built-in Bluetooth).

However, an additional USB Bluetooth adapter, also for GX devices with built-in Bluetooth, allows for limited relocation of the Bluetooth radio (via a USB cable extension) close to other supported Bluetooth devices that might not otherwise be reachable.

Note for Cerbo GX units built up to and including serial number HQ2207: The built-in Bluetooth connection is disabled when the internal CPU temperature exceeds 53 degrees C (influenced by load and/or ambient temperature). For reliable operation it is necessary to use a USB Bluetooth adapter. Devices manufactured later (HQ2208 and later) do not require an additional USB Bluetooth adapter. Note that this limitation does not apply to the Cerbo-S GX.

External USB Bluetooth adapters that have been tested and known to work:

USB Bluetooth adapter | ||||

|---|---|---|---|---|

Insignia (NS-PCY5BMA2) | Logilink BT0037 | TP-Link UB400(UN) | Kinivo BTD-400 | Ideapro USB Bluetooth adapter 4.0 |

Ewent EW1085R4 | Laird BT820 | Laird BT851 | - | - |

A list of additional adapters that are also being tested, as well as adapters that have been tested and are known not to work, is available in this community thread.

Installation procedure

Make sure that Bluetooth is enabled in the Bluetooth menu (enabled by default).

Go to the Settings → I/O → Bluetooth sensors menu and then click Enable to enable Bluetooth temperature sensors.

The Ruuvi sensors come supplied with a removable plastic pull tab. This prevents it from discharging while on the shelf. Pull out the plastic tab and the unit will start transmitting its temperature information.

The sensor should appear in the menu, "Ruuvi ####" - with a 4 hexidecimal device ID, enable the specific Ruuvi sensor.

The Bluetooth adapters submenu displays a list of available Bluetooth adapters. The menu option Continuous scanning permanently scans for new Bluetooth sensors. Note that this option affects the WiFi performance of the GX device. Only enable this option if you need to search for new Bluetooth sensors. Otherwise, leave this option disabled.

If you have multiple sensors, you may wish to physically write this device ID on the sensor case itself to help keep track.

The sensor should now be visible in the main menu - by default it is labelled 'Generic temperature sensor (##)'

It is possible inside the temperature sensor menu to adjust the type, and also to set a custom name.

Battery Life and Status for Ruuvi Sensors:

The Ruuvi sensors use a replaceable CR2477 3V lithium coin cell, which is estimated to last more than 12 months, depending on the ambient temperature.

Battery Information:

The internal battery voltage and status are displayed in the sensor's menu.

Battery Status Indicators:

OK status: Battery voltage ≥ 2.50V

Sensor battery low status: Battery voltage ≤ 2.50V

Low Battery Warning:

A low battery warning will appear on the Remote Console. If the GX device reports to VRM, the warning will also appear there.

The warning threshold is temperature-dependent:

Below 20°C: Threshold is 2.0V

Between -20°C and 0°C: Threshold is 2.3V

Above 20°C: Threshold is 2.5V

It is possible to update the firmware for the Ruuvi with Ruuvi's own separate phone app, though this is not necessary unless you are experiencing issues.

5.10. Connecting IMT Solar Irradiance, Temperature and Wind Speed Sensors

Ingenieurbüro Mencke & Tegtmeyer GmbH (IMT) offer a range of digital silicon irradiance sensor models within the Si-RS485 series that are all compatible with a Victron GX device.

Compatibility

The optional/additional external module temperature, ambient temperature and wind speed sensors are also supported.

Optional/additional external sensors are either connected to the solar irradiance sensor with pre-installed plugs or pre-wired to the solar irradiance sensor (external module and ambient temperature only). When external sensors are connected via an appropriate solar irradiance sensor, all measurement data is transmitted to the Victron GX device with the single interface cable.

Each model solar irradiance sensor within Si-RS485 series has a different capability with regards to external sensors (or comes with an external sensor pre-wired), so carefully consider any future desires/requirements before initial purchase.

It is also possible to connect an independent IMT Tm-RS485-MB module temperature sensor (visible as ‘cell temperature’) or IMT Ta-ext-RS485-MB ambient temperature sensor (visible as ‘external temperature’) directly to the Victron GX device, without a solar irradiance sensor or in addition to one.

Operation

The IMT Si-RS485 series solar irradiance sensors operate using an RS485 electrical interface and Modbus RTU communication protocol.

The Victron GX device must be running version 2.40 or later.

IMT Sensors with firmware versions before v1.53 are supported - for more information about this, please contact IMT.

The physical connection to the Victron GX device is via USB port and requires a Victron RS485 to USB interface cable.

A suitable external DC power source (12 to 28 VDC) is also required - the sensor is NOT powered via USB.

Recent IMT models feature a second temperature sensor which is also supported.

Wiring Connections

The schematic in the installation guide below depicts the wiring configuration in a typical installation.

|

Wire connections

Si-Sensor | Victron RS485 to USB interface | Signal |

|---|---|---|

Brown | Orange | RS485 Data A + |

Orange | Yellow | RS485 Data B - |

Red | - | Power Pos - 12 to 28VDC |

Black | Power Neg/Gnd - 0VDC | |

Black (thick) | - | Ground / Cable Shield / PE |

- | Red | Power Pos - 5VDC (not used) |

- | Black | Power Neg/Gnd - 0VDC (not used) |

Brown | Terminator 1 - 120R (not used) | |

Green | Terminator 2 - 120R (not used) |

Installation Notes

The maximum DC power supply voltage permitted for the IMT Si-RS485 series solar irradiance sensor range is 28.0VDC - accordingly for 24V and 48V battery banks/systems an appropriate Victron DC-DC converter (24/12, 24/24, 48/12 or 48/24) or AC-DC adaptor must be utilised in the installation.

For 12V battery banks/systems the IMT Si-RS485 series solar irradiance sensor range may be powered directly from the battery bank and will continue to operate down to minimum voltage of 10.5V (as measured at the sensor, account for voltage drop in the cable).

For detailed wiring/installation notes and specifications refer to the IMT Si-RS485 series solar irradiance sensor 'Quick Reference Guide' and Victron RS485 to USB interface cable ‘Datasheet’.

To ensure signal integrity and robust operation, particularly ensure that;

Extension cabling complies with the minimum cross-sectional area specifications in the related table - dependent on DC supply voltage and cable length

Extension cabling has appropriate shielding and twisted pair cores

The original cable attached to the Victron RS485 to USB interface is reduced to a maximum length of 20cm in installations where the total cable length is over 10m or there are installation/site specific interference issues – in this case appropriate/high quality cabling should be used for the entire cable length, rather than only for the extension length

Cabling is installed separated/away from the main DC or AC power cabling

All wiring is properly terminated (including unused wires) and properly isolated from weather/water ingress

The sensor housing is not opened or tampered with during installation - as sealing integrity will be compromised (and warranty void)

The IMT Si-RS485TC series solar irradiance sensor includes internal Galvanic Isolation (up to 1000V) between power supply and RS485 Modbus circuits, accordingly the non-isolated Victron RS485 to USB interface is suitable for most installations.

However, if an isolated RS485 to USB interface is preferred the only compatible device is Hjelmslund Electronics USB485-STIXL (any others type will not be recognised by the GX device).

Multiple Sensors

It is possible to connect multiple IMT Si-RS485 series solar irradiance sensors to a common Victron GX device, however a dedicated Victron RS485 to USB interface is required for each individual unit.

Multiple units cannot be combined on a single interface (as this is not supported by the related Venus OS software).

Configuration

There is normally no need for any special/additional configuration – the default ‘as shipped’ configuration is compatible for communication with a Victron GX device.

However, in cases where the IMT Si-RS485 series solar irradiance sensor has been previously used in another system and/or the settings changed for any reason, it is necessary to restore the default configuration before further use.

To revise the configuration, download the IMT 'Si-MODBUS-Configuration software tool'. Follow the instructions in the IMT ‘Si Modbus Configurator Documentation’. and check/update the following settings:

MODBUS Address: 1

Baud Rate: 9600

Data Format: 8N1 (10 Bit)

For further support related to configuration of the IMT Si-RS485 Series irradiance sensors please contact IMT Solar directly.

User Interface - GX device

Upon connection to the Victron GX device and power up the IMT Si-RS485 Series irradiance sensor will be automatically detected within a few minutes and appear in the 'Device List' menu.

Within the ‘IMT Si-RS485 Series Solar Irradiance Sensor’ menu all available parameters will be automatically displayed (dependent on the sensors connected) and update in real time.

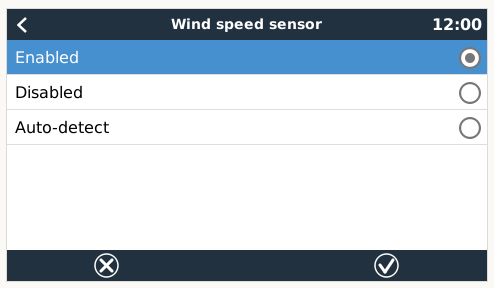

Within the ‘Settings’ sub-menu it is possible to manually enable and disable any optional/additional external sensors that are connected to the IMT Si-RS485 Series irradiance sensor.

|  |

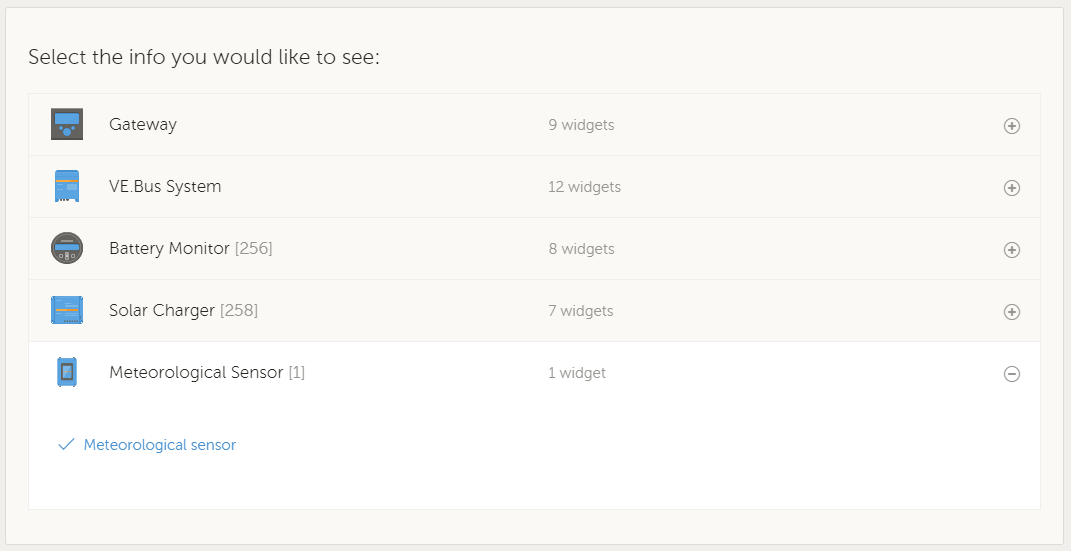

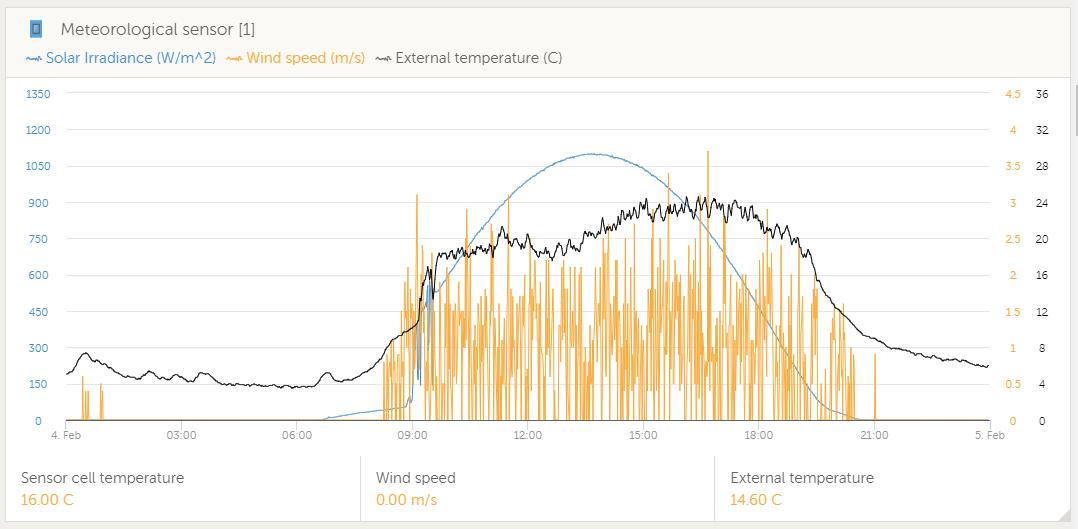

5.10.1. Data Visualisation - VRM

To review logged historical data on the VRM portal, expand the ‘Meteorological Sensor’ widget list and select the ‘Meteorological Sensor’ widget.

|

Data from all available sensor types will be automatically displayed in the graph. Individual sensors/parameters can also be disabled/enabled by clicking on the sensor name/legend.

|

5.11. ComAp InteliLite 4 series genset controller support

For detailed information, see here.

5.12. DSE- Deep Sea generator controller support

For detailed information, see here .

5.13. Reading generic alternator data from compatible NMEA 2000 DC sensors

Venus OS supports NMEA 2000 DC sensors that can be used to read alternator voltage, current and temperature from a generic alternator. Please note that the data is only displayed. They are not used for further calculations or functions.

The third-party NMEA 2000 DC sensors must meet the following requirements:

The NMEA 2000 device class must be 35 Electrical Generation.

The NMEA 2000 device function must be 141 DC Generator.

DC type must be set to alternator in PGN 127506 DC Details.

Voltage, current and temperature must be transmitted in PGN 127508 Battery Status.

Most NMEA 2000 DC sensors are expected to work.

Compatibility has been tested with:

To connect a NMEA 2000 network to the VE.Can port on the GX device, which both have a different style connector, there are two solutions:

The VE.Can to NMEA 2000 cable: By either inserting or leaving out the fuse, it allows to power the NMEA 2000 network with Victron equipment or not. Take note of the below warning.

The 3802 VE.Can Adapter by OSUKL. Its advantage is that it lends itself well to connecting a single NMEA 2000 device such as a tank sender into a VE.Can network. It's also able to power a lower voltage NMEA 2000 network directly from a 48V Victron system.

Warning and solution for 24V and 48V systems

Whilst all Victron components accept up to 70V input on their CAN-bus connections, some NMEA 2000 equipment does not. They require a 12V powered NMEA 2000 connection, and sometimes work up to 30 or 36V. Make sure to check the datasheet of all used NMEA 2000 equipment. In case the system contains NMEA 2000 that requires a network voltage below the battery voltage, then either see above 3802 VE.Can Adapter by OSUKL, or alternatively install the VE.Can to NMEA 2000 cable without it’s fuse, and provide suitable power to the NMEA 2000 network using for example a NMEA 2000 power adapter cable – which is not supplied by Victron. The VE.Can port on the GX device does not need external power to operate.

5.13.1. Wakespeed WS500 alternator regulator support

Introduction

The WS500 is an external smart alternator regulator with CAN-bus and NMEA 2000 communication, which is especially applicable in Marine and RV applications. The Wakespeed WS500 is supported by Venus OS and offers the possibility to monitor the performance of your alternators via a GX device.

Requirements

Necessary requirements for the integration of the WS500 are:

VenusOS firmware v2.90 or higher installed on your GX device

Wakespeed WS500 firmware 2.5.0 or higher installed on the WS500 controller

The WS500 must connect to the VE.Can port of the GX device. It is not possible to monitor the WS500 when connected to the BMS-Can port of a Cerbo GX.

Wiring the WS500 to VE.Can

Both, the WS500 and VE.Can, use RJ45 connectors for their CAN ports.

However, both have different pin outs. This means that a normal (straight UTP cable) network cable cannot be used. A crossover cable is required. This crossover cable must be made by yourself. The following diagram reflect the pin out of the two devices.

The important pins to look at are pin 7 and pin 8 for CAN-H and CAN-L on the VE.Can side and pin 1 and 2 for Can-H and CAN-L on the WS500 side.

Therefore a cable is needed where pin 1 and 2 on one side are connected to pin 7 and pin 8 on the other side. Pin 7 goes to pin 1 and pin 8 to pin 2.

The RJ45 connector with pin 7 and 8 on one end connects to the VE.Can port of the GX device. The other end of the cable with pin 1 and 2 connects to the WS500 controller. Both sides must be terminated.

The cable colors do not matter for the do-it-yourself cable. Wakespeed also offers a ready-configured cable with a blue RJ45 connector on one end that must be connected to the VE.Can port.

Note

Please note that the black terminators supplied by Wakespeed and the blue terminators supplied by Victron are not interchangeable. Therefore: insert the Victron terminator on the Victron side of the network, and insert the Wakespeed terminator into the Wakespeed.

Wiring Example

The example below shows an overview of the recommended wiring based on an installation with a Lynx Smart BMS, Lynx Distributors and a Cerbo GX.

The correct placement of the alternator shunt (not to be confused with the shunt of the BMV or SmartShunt) is important here for the correct connection of the current sense wire.

For complete wiring between the WS500 and alternator, see the WS500 and the alternator manual.

GX device user interface for WS500

Once the WS500 is connected to the GX device, the Device list contains an entry for the regulator.

The WS500 menu then provides the following information and data:

Output: voltage, current and power as reported from the alternator regulator

Temperature: the alternator temperature as measured by the WS500 temperature sensor

State: the charging state of the WS500

Off when not charging

Bulk, Absorption or Float when the WS500 is using its own charging algorithm

External Control when controlled by a BMS such as Lynx Smart BMS

Network Status:

Standalone, if the regulator is working on its own

Group Master, when it is supplying charging targets to another WS500 device

Slave, when it is taking charging directions from another device such as a WS500 or a BMS

Error: reflects any error state the WS500 might be in. The details of all error codes and messages can be found in the Wakespeed Configuration and Communications guide. See also the appendix for error #91 and error #92

Field Drive: report on the % of field drive being sent by the WS500 to the alternator on the field connection

Speed: the speed in RPM at which the alternator is spinning. This is as reported by the stator feed and if this is wrong can be adjusted by setting the Alt Poles option within the Wakespeed SCT configuration line

Engine Speed: reported in RPM. This is reported by either

calculation based on the alternator speed and the Eng/Alt drive ratio as set by the SCT configuration line

NMEA 2000, if the WS500 is receiving engine RPM from PGN127488

J1939, if the WS500 is receiving engine RPM from PGN61444

It is also possible to create a custom name for the WS500 in the Device menu. This triggers the WS500 to update the $SCN configuration line of the regulator.

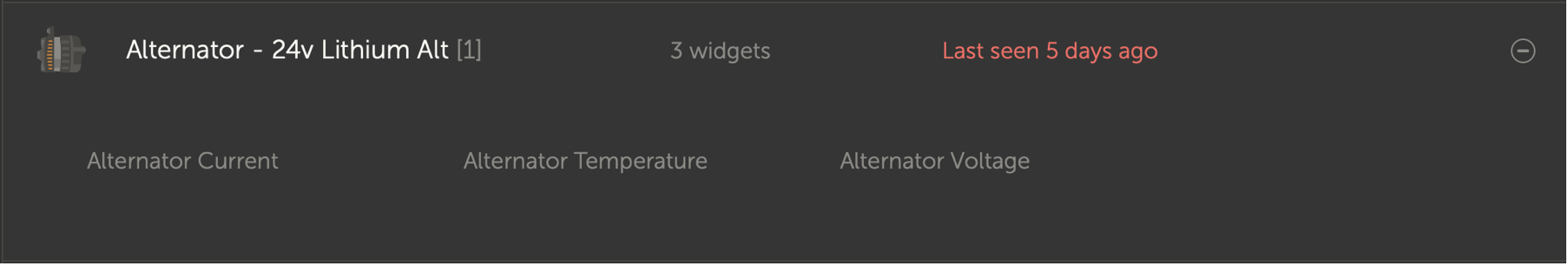

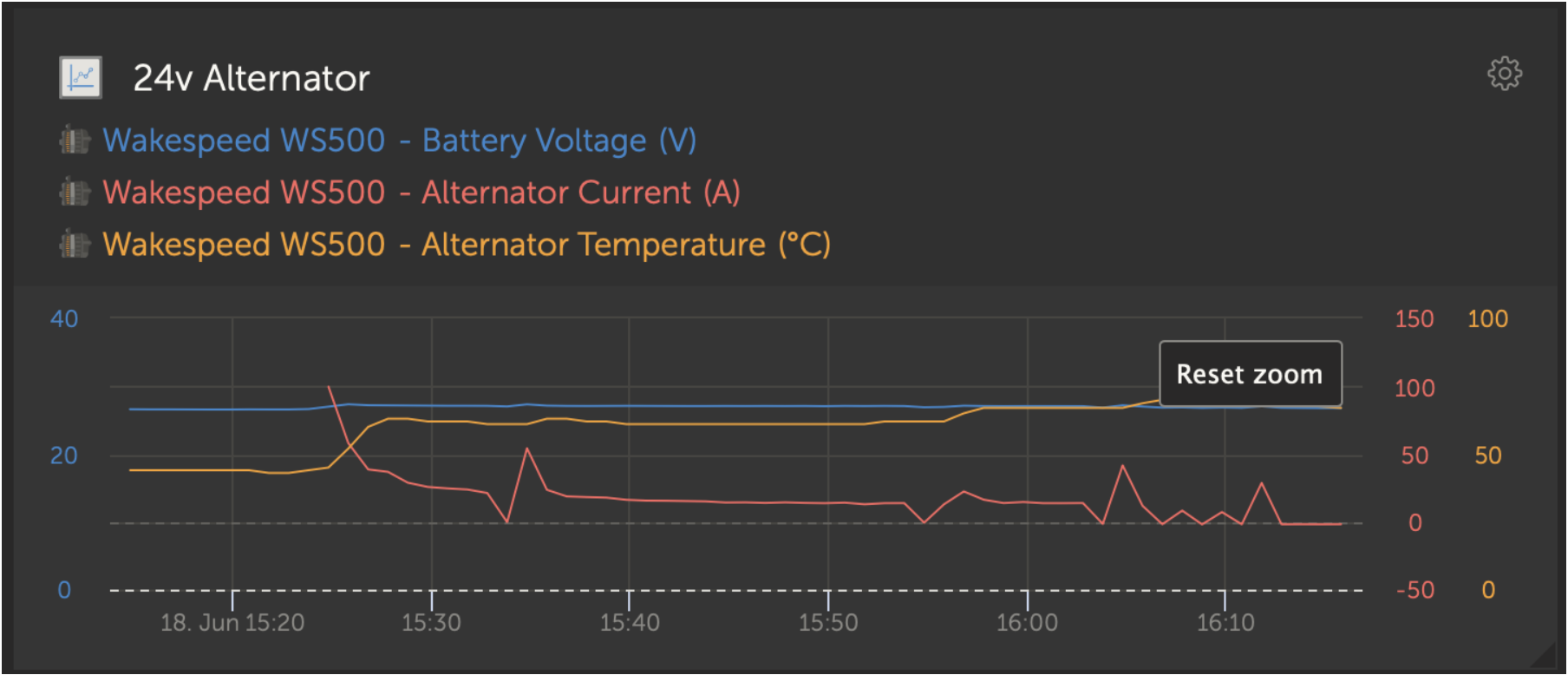

WS500 data on the VRM Portal

WS500 data that can be displayed on our VRM portal is current, voltage and temperature.

Currently 3 widgets are available on VRM

VRM custom widget showing WS500 voltage, current and temperature

Troubleshooting & FAQ

For further assistance and troubleshooting please contact Wakespeed support directly.

Error code #91 and #92

Venus OS will report all errors that can be generated by the WS500 as defined within the Wakespeed Communications and Configuration guide. In systems with integrated BMS, the following errors are critical as long as the events are active and require special attention.

#91: Lost connection with BMS

The WS500 has lost communication with the BMS and will drop into the configured get home mode. As soon as communication is restored with the BMS, it will revert to following the charging goals as set by the BMS.

#92: ATC disabled through feature IN

The BMS has signalled a charge disconnect event through the feature in wire and the WS500 has therefore reverted to an Off status.

Current and power data are not displayed in the WS500 device menu

This does not constitute a problem and simply relates to how the system is installed and intended to be.

No alternator shunt[1] installed

Alternator shunt installed but not properly configured. Check the ShuntAtBat setting and the Ignore Sensor setting using the Wakespeed configuration tools.

[1] The alternator shunt is a shunt that can be installed in series with the alternator to provide readout of alternator output current and power. Its sense wiring connects directly to the WS500. This is an optional feature that is only for display purposes. If the shunt is not installed, the GX device will show other alternator data, such as field % and output voltage etc., but not the alternator output current and power.

FAQ

Q1: Is the alternator output current (if actually measured) used for anything other than just display purposes?

A1: For the time being it's just for display purposes. Perhaps sometime in the future there will be DVCC integration, where the GX device controls the amount of current you want the WS500 to generate, and then the GX device splits the desired charge current between the WS500 and, for example, MPPTs.

Q2: What is the battery output current used for and can it be read over the canbus by a Lynx Smart BMS, other battery monitors or even a GX device?

A2: Yes, the current can be read out via canbus and Lynx Smart BMS.

In this case the WS500 shunt can be configured for the alternator and thus report the amount of current the alternator is producing. The Lynx Smart BMS current is used by the WS500 to ensure that no more than what the battery needs goes into the battery. So if the battery calls for 100A and the WS500 reports 200A at the alternator, 100A will be used to support the loads. It offers a greatly improved calculation for the DC load.

Q3: If the system includes a Lynx Smart BMS, are there any wiring recommendations?

A3: Yes. We have created extensive system examples that show the complete wiring and have been supplemented with important additional information. For example a catamaran system with two WS500 or a system equipped with an additional alternator controlled by one WS500. These examples can be used as a basis for your own system.

These system examples can be downloaded from the product page of the Lynx Smart BMS.

Q4: If the system does not include a Lynx Smart BMS, how do you recommend wiring?

A4: Wakespeed provides a quick start guide showing how to configure the regulator via DIP switches and an overview of all wiring connections on the wiring harness that comes with the unit.

The WS500 product manual contains additional wiring diagrams that show in detail how the wiring harness is wired.

Note that the shunt should be connected to the battery and the WS500 configured with the shunt on the battery.